| A.Special Formula |

|

Special Formula |

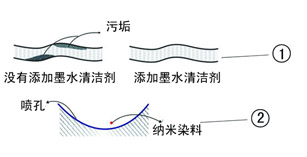

1. Special formula:the ink contains deionized water, special inkjet dye, surfactant, organic solvent, dispersant, drying agent, ultraviolet absorber etc.

2. Add ink cleaning agent:it dissolves the dirt in ink and nozzle effectively.

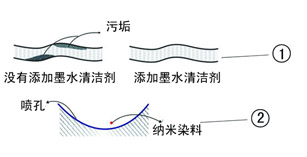

3. Use imported nanometer pigment:the diameter is 1/100 of nozzle apperture.

4. Add special permeable agent: the adjacent two diffierent ink's penetration under control through special permeable agent, ensure the high precision printing.

| B.National Standard |

|

* Quality Standard: Q/HDYYJ001-2006

* Environmental Test Report: TQT00-C0168-2006

* Physicochemical Index:conductive rate: 3.16 (ms/cm)

* Viscosity: 3.6 (mpa.s)

* Surface Tension: 30.2 (mn/m)

* PH: 7.46

* Weather Resistance: 4-5

* Bacterial Content:200nm(strict filtration)

* Spectral Absorption Value and Peak Position: 582 ABS: 0.411

|

|

| C.Strict Texting |

|

1. Keep sealed ink under -15℃ for 48 hours, recovery after 2 hours under normal temperature, the printing Color and picture is the same.

2. Keep sealed ink under 60℃ for 24 houes, recovery after 2 hours under normal temperature, the printing Color and picture is the same.

3. Keep sealed ink ubder sunshine for 30 days, the ink is stability.

4. Centrifugal Test(3000 rpm)2 hour,no precipitation.

|

5.

Tne ink in the pipeline without leakage, not dry, not plug nozzle.

6. Keep the ink in printer for 30days, then print, not plug nozzle.

7. Non-toxic, low corrosion, no harm to health. |

|

keep ink under 70℃ |

massive text |

| D.Strict Production Process |

|

1. Imported raw material: imported ink additives, ensure that the quality of ink.

2. Dust-free workshop.

3. Three grade filtration: through three stage filtration.

4. Air pumping mixing: remove the tiny bubbles in the ink , avoid air plugged.

5. Heating solution: ink composition can mixed and dissolved through heating.

|

|

|

|